Robotic Welding: How Manufacturers Achieve ROI, Part 4

Robotic Welding: Process Optimization with IIoT

The future of manufacturing is all about connection. As industries evolve, high-connectivity systems are becoming essential, and for good reason. The Industrial Internet of Things (IIoT) — a highly connected environment where machines, operators, and business systems communicate seamlessly — offers significant opportunities for process optimization and productivity, especially when it comes to robotic welding and its return on investment. Forward-thinking manufacturers like General Motors, which pioneered robotic automation in the 1960s, have already begun leveraging these technologies to stay ahead of the curve. But what exactly does IIoT bring to the table? And how can it help manufacturers today?The Challenges of Manual Welding

Before diving into IIoT, it’s important to understand the limitations of manual welding. In traditional setups, gaining meaningful insights into the welding process is difficult. While overall throughput may be tracked, granular data — such as weld quality, consistency, or even minor variations — is often missing. This lack of visibility hinders continuous improvement. Without detailed information, it's hard to identify the root causes of issues or optimize processes effectively. Robotic welding, by contrast, offers built-in connectivity and data collection capabilities that make it possible to monitor every aspect of the welding process.Enhancing Connectivity in Robotic Welding

With robotic welding systems, you can collect detailed data either directly from the power source or through third-party integration. This allows companies to track individual welds, diagnose defects, and uncover inefficiencies across the entire production line. Beyond basic monitoring, IIoT connectivity opens up new possibilities. For example, it enables predictive maintenance, so you know when a machine needs servicing before it fails. More advanced applications include machine learning, where robots can self-correct minor inconsistencies in real time, minimizing downtime and improving output. In short, IIoT gives manufacturers a comprehensive view of their operations — from raw materials to finished products — and how robotic welding fits into the bigger picture.Why IIoT Matters for Manufacturing Today

IIoT is not just a trend — it's the future of smart manufacturing. It empowers companies to boost productivity, reduce waste, and stay competitive in an increasingly global market. Manual welding, while still used in some cases, lacks the data-driven insights and scalability needed for large-scale or high-precision projects. Robotic welding, however, is designed with connectivity in mind. It provides rich data that can be used to refine processes, improve quality, and support broader digital transformation efforts.Conclusion: Realizing ROI Through Smart Welding

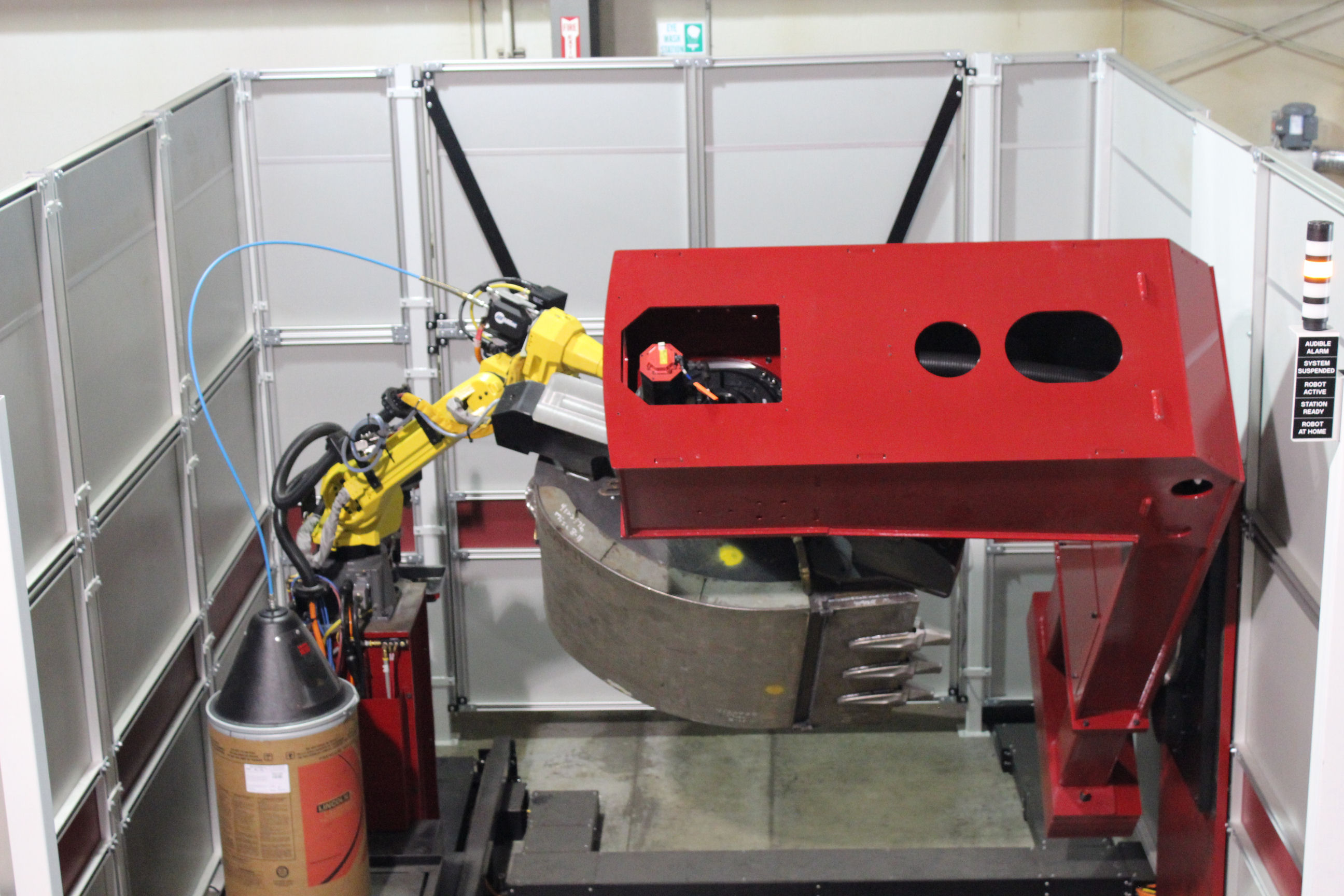

In this series, we’ve explored how robotic welding reduces rework, lowers material waste, increases efficiency, improves safety, and enables IIoT integration for smarter production. These benefits help manufacturers achieve a strong return on investment and remain competitive in today’s fast-paced industry. ROI is more than just a number — it’s a strategic decision. By adopting robotic welding, businesses can unlock new levels of performance, quality, and scalability. If you're considering automation or have questions about robotic welding, don’t hesitate to reach out to Genesis Systems. We’re here to help you navigate the future of manufacturing. Explore the full Robotic Welding Series: How Manufacturers Find ROI: - Robotic Welding Series Part 1: Avoiding Rework and Excessive Material Consumption - Robotic Welding Series Part 2: Increased Uptime and 85% Efficiency - Robotic Welding Series Part 3: Resolving Labor Shortages and Workplace Safety Posted in Robotic WeldingAutomatic Sand Blasting Machine

Automatic Sand Blasting Machine,Special-shaped sand blasting machine,Automated sand blasting machine,Automated Sandblasting Systems,Automatic sandblaster machine,sandblasting machine

Foshan Sandwell Machinery Co.,ltd , https://www.sandwellsand.com